Wettability of Separator Sheets in Lead Acid Batteries

Mentor 1

Benjamin Church

Location

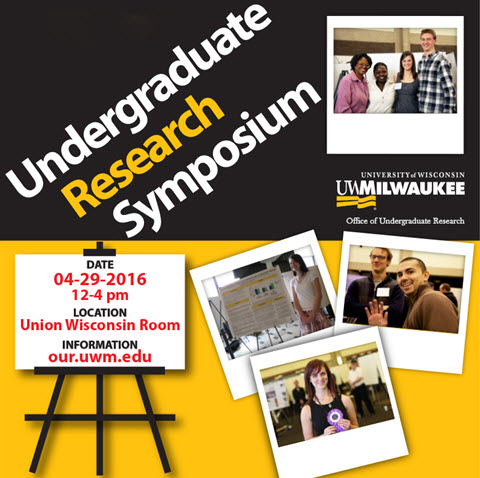

Union Wisconsin Room

Start Date

29-4-2016 1:30 PM

End Date

29-4-2016 3:30 PM

Description

With the growing need for energy efficiency in the fields of motors, marine technologies and robotics, the demand for “Absorbent Glass Mat” (AGM) Lead Acid Battery is at an all-time high. This battery is extremely popular because of its reduced weight and increased reliability. One of the greatest challenges to produce effective lead acid batteries is contained in its manufacturing process. For this the understanding of the wetting kinetics of the fiberglass separators between anodes and cathodes of the battery become of particular concern. After the dry battery has been created, the electrolyte must be injected into the battery, where it will wet (or absorb into) the separator sheet, anode and cathode. This process is one of the slower parts of the manufacturing process, and thus a limiting factor for production, which effectively translates to industrial efficiency. Thus, a quantitative measurement for wettability can improve the understanding of wetting behavior, which can have potential performance or economic impacts. A replicable methodology is developed to quantify such wettability of these separator sheets and the method will be used to study relation between the wetting rates and glass mat structures. There is not currently a comprehensive method for determining wetting rates of the materials, making it largely a trial and error situation. Wetting rate of multiple separator sheets can be employed to better understand and manipulate the relationships of structures to wetting rates.

Wettability of Separator Sheets in Lead Acid Batteries

Union Wisconsin Room

With the growing need for energy efficiency in the fields of motors, marine technologies and robotics, the demand for “Absorbent Glass Mat” (AGM) Lead Acid Battery is at an all-time high. This battery is extremely popular because of its reduced weight and increased reliability. One of the greatest challenges to produce effective lead acid batteries is contained in its manufacturing process. For this the understanding of the wetting kinetics of the fiberglass separators between anodes and cathodes of the battery become of particular concern. After the dry battery has been created, the electrolyte must be injected into the battery, where it will wet (or absorb into) the separator sheet, anode and cathode. This process is one of the slower parts of the manufacturing process, and thus a limiting factor for production, which effectively translates to industrial efficiency. Thus, a quantitative measurement for wettability can improve the understanding of wetting behavior, which can have potential performance or economic impacts. A replicable methodology is developed to quantify such wettability of these separator sheets and the method will be used to study relation between the wetting rates and glass mat structures. There is not currently a comprehensive method for determining wetting rates of the materials, making it largely a trial and error situation. Wetting rate of multiple separator sheets can be employed to better understand and manipulate the relationships of structures to wetting rates.