Design of Experiment: Rotating Two-Pass Rectangular Channel Representing Internal Cooling of Gas Turbine Blades

Mentor 1

Ryo Amano

Mentor 2

Saman Beyhaghi

Location

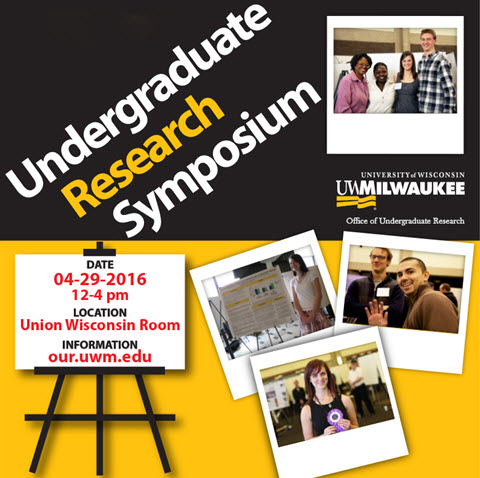

Union Wisconsin Room

Start Date

29-4-2016 1:30 PM

End Date

29-4-2016 3:30 PM

Description

The objective of this project is to create a rotating apparatus to collect data experimentally, optimizing industry-used serpentine cooling passages internal to gas turbine rotor blades. The end result is to obtain previously computer-simulated results in which the addition of rotation increased the effective surface cooling on the stationary case. For this study, a pulley-driven rotating assembly consisting of a hollow drive-shaft, four-way connecting piece, and rectangular two-pass channel have been designed. Thermocouples are to be affixed to points within the two-pass channel to monitor the temperature profile of the flow. This apparatus is to rotate at very high speeds to better simulate turbine operating speeds, creating many design and safety concerns that have needed to be addressed through the different stages of design including but not limited to research into machine guarding and failure of parts under rotational forces.

Design of Experiment: Rotating Two-Pass Rectangular Channel Representing Internal Cooling of Gas Turbine Blades

Union Wisconsin Room

The objective of this project is to create a rotating apparatus to collect data experimentally, optimizing industry-used serpentine cooling passages internal to gas turbine rotor blades. The end result is to obtain previously computer-simulated results in which the addition of rotation increased the effective surface cooling on the stationary case. For this study, a pulley-driven rotating assembly consisting of a hollow drive-shaft, four-way connecting piece, and rectangular two-pass channel have been designed. Thermocouples are to be affixed to points within the two-pass channel to monitor the temperature profile of the flow. This apparatus is to rotate at very high speeds to better simulate turbine operating speeds, creating many design and safety concerns that have needed to be addressed through the different stages of design including but not limited to research into machine guarding and failure of parts under rotational forces.