Structural Health Monitoring Systems with Integrated Sensors and Actuators to Detect and Locate Structural Flaws

Mentor 1

Dr. Nathan Salowitz

Location

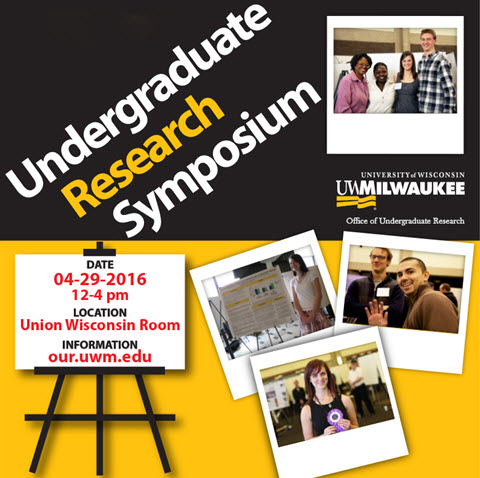

Union Wisconsin Room

Start Date

29-4-2016 1:30 PM

End Date

29-4-2016 3:30 PM

Description

Acoustic ultrasonic based structural health monitoring systems use piezoelectric transducers to generate and detect waves that propagate through a structure to detect cracks and other potential flaws in real time. Application could vastly improve the safety and performance of engineered systems, such as bridges, buildings, spacecraft and airplanes. Location of damage is critical to this capability, and prohibitively challenging with other forms of Structural Health Monitoring, but direct path mapping of ultrasonic signals is a promising method for damage location. The test sample used in the experiment is composed of five piezoelectric sensors and actuators placed on a sheet of aluminum. A waveform generator and amplifier allow for a desired waveform to be actuated from one of the piezoelectrics. This allows the other piezoelectrics to act as sensors and a difference of scatter energies can be found and compared using matlab. Results are taken from a pristine sample (sample with no damage), giving baseline data. This baseline data can be compared to data collected from another pristine sample and a damaged sample. The scatter energy differs between the damaged and pristine data, allowing for a comparison to be made. The scatter energy difference can then be analyzed to determine the location of the damage on the sheet of aluminum. The complexity of the signals propagated, containing multiple wave modes and reflections, makes analysis challenging; however, calculating the difference in scatter energy can determine the location of the damage. Unlike previous experiments, which were only able to detect damage, by gathering data over multiple paths, comparisons between the scatter energies of differing paths, allows for a location to be determined.

Structural Health Monitoring Systems with Integrated Sensors and Actuators to Detect and Locate Structural Flaws

Union Wisconsin Room

Acoustic ultrasonic based structural health monitoring systems use piezoelectric transducers to generate and detect waves that propagate through a structure to detect cracks and other potential flaws in real time. Application could vastly improve the safety and performance of engineered systems, such as bridges, buildings, spacecraft and airplanes. Location of damage is critical to this capability, and prohibitively challenging with other forms of Structural Health Monitoring, but direct path mapping of ultrasonic signals is a promising method for damage location. The test sample used in the experiment is composed of five piezoelectric sensors and actuators placed on a sheet of aluminum. A waveform generator and amplifier allow for a desired waveform to be actuated from one of the piezoelectrics. This allows the other piezoelectrics to act as sensors and a difference of scatter energies can be found and compared using matlab. Results are taken from a pristine sample (sample with no damage), giving baseline data. This baseline data can be compared to data collected from another pristine sample and a damaged sample. The scatter energy differs between the damaged and pristine data, allowing for a comparison to be made. The scatter energy difference can then be analyzed to determine the location of the damage on the sheet of aluminum. The complexity of the signals propagated, containing multiple wave modes and reflections, makes analysis challenging; however, calculating the difference in scatter energy can determine the location of the damage. Unlike previous experiments, which were only able to detect damage, by gathering data over multiple paths, comparisons between the scatter energies of differing paths, allows for a location to be determined.