Optimization of Magnetostrictive Nanocellulose Composites

Mentor 1

Dr. Chiu Tai Law

Location

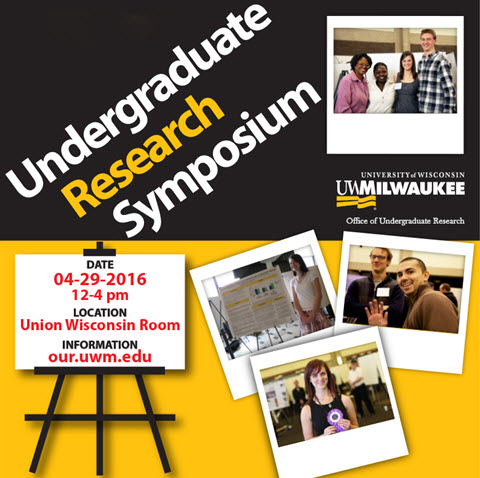

Union Wisconsin Room

Start Date

29-4-2016 1:30 PM

End Date

29-4-2016 3:30 PM

Description

Terfenol-D, first synthesized in the 1970s, exhibits the highest magnetostrictive properties of all alloys. It is costly to produce and difficult to machine. It also exhibits low ductility and tensile strength. Terfenol-D particles can be integrated into a composite in order to reduce manufacturing cost, while still producing similar magetomechanical properties as well as increasing ductility. Previous studies have shown high potential in Terfenol-D/Epoxy Composites. In this study, a new Magnetostrictive composite composed of Terfenol-D and Cellulose Nanofibral (CNF) was tested to produce similar Magnetomechanical properties to that of monolithic Terfenol-D. Optimal volume fractions of Terfenol-D to CNF were calculated from experimental data. Optimum volume fraction of Terfenol-D/CNF composites was calculated through measured data of the strain contraction between Terfenol-D and CNF particles (a) per percent water content (DWc) of pure CNF as it cures. An axial stress (s) of 5 MPa was considered the minimum compressive stress needed in order to orient domains transversely and allow magnetization jumping. Other constants tested were the Young’s modulus of CNF and Terfenol-D.

Optimization of Magnetostrictive Nanocellulose Composites

Union Wisconsin Room

Terfenol-D, first synthesized in the 1970s, exhibits the highest magnetostrictive properties of all alloys. It is costly to produce and difficult to machine. It also exhibits low ductility and tensile strength. Terfenol-D particles can be integrated into a composite in order to reduce manufacturing cost, while still producing similar magetomechanical properties as well as increasing ductility. Previous studies have shown high potential in Terfenol-D/Epoxy Composites. In this study, a new Magnetostrictive composite composed of Terfenol-D and Cellulose Nanofibral (CNF) was tested to produce similar Magnetomechanical properties to that of monolithic Terfenol-D. Optimal volume fractions of Terfenol-D to CNF were calculated from experimental data. Optimum volume fraction of Terfenol-D/CNF composites was calculated through measured data of the strain contraction between Terfenol-D and CNF particles (a) per percent water content (DWc) of pure CNF as it cures. An axial stress (s) of 5 MPa was considered the minimum compressive stress needed in order to orient domains transversely and allow magnetization jumping. Other constants tested were the Young’s modulus of CNF and Terfenol-D.